Timber frame construction uses prefabricated (off-site manufacture) external and internal stud walls, floor joists and roof trusses to form the super-structure which is a complete structural frame that transfers the vertical and horizontal loads to the foundations. The timber frame structure can then be clad in brick, wood, fibre cement board, rendered or tiled which will act as the decoration for the home as well as weather protection. The external cladding would be installed on site once the prefab structure is in place. The build process is shown in the images below which respectively depict…

- Ground floor open panel timber frames

- First floor timber frame panels installed once joists and flooring fixed

- First floor joists installed to the top of the ground floor panels

- Inside view from first floor to roof trusses

- Traditional green oak section to ground floor to create glazed single storey extension

- Finished timber frame house supplied and fitted by Vision Development

Floor to ceiling height panels form each storey and the floor deck of one floor also acts as the erection platform of the next. This is shown in the pictures below which respectively depict…

- Posi metal web joists manufactured and installed by Vision Development

- 22mm chipboard flooring fitted to the top of joists to create first floor level

- Internal first floor panels fitted to sole plates on chipboard flooring to create internal walls

Please follow these links below which provide further information on the process of installing a timber frame structure…

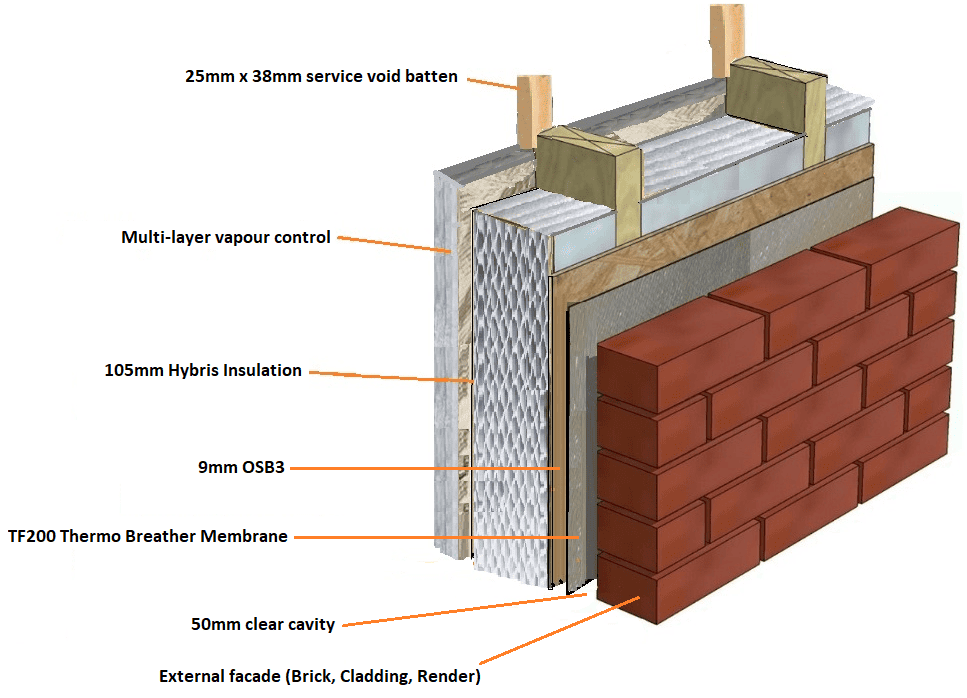

Below is a typical open panel timber frame build up for an external wall. There are alternatives to the materials used and we often tailor our panels to suit our Client’s specific U Values and requirements.

Timber Frame Construction

Most timber frame constructions in the UK use prefabricated panels produced by specialist companies such as Vision Development. Factory production of these timber frame panels ensures that they are accurately manufactured to precise tolerances in a controlled factory environment rather than being constructed outside on a building site at the mercy of the weather.

The timber frame panels are rapidly erected on site and, with a roof structure formed from trussed rafters (dependent on design) a weather proof building can be created in just 2-3 weeks. This enables work to continue in sheltered conditions within the building whilst the outer cladding and roof finishes are applied. This not only saves time but also allows decoration to be carried out soon after completion of the construction without risk of cracking and deterioration of finishes.

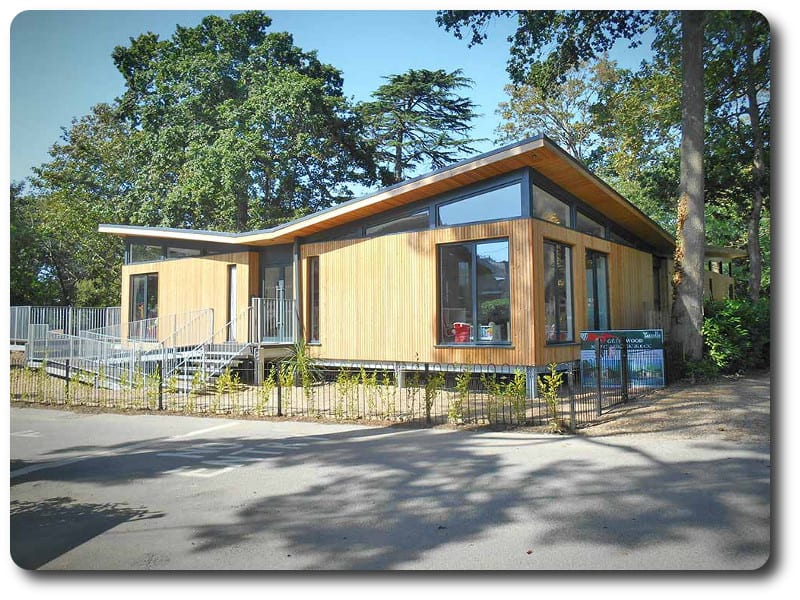

Timber frame construction is not just for houses – it is also used extensively for schools, hotels, offices, blocks of flats and sporting facilities. Timber frame construction can be used for buildings of up to eight storeys in height. With the increase in mixture of timber and metal (metal web posi joists & structural beams) larger spans are achievable with cable/pipe accessible floors for first fix services.

Timber Frame Panels

Timber frame wall panels are made up of softwood vertical studs and horizontal rails with a wood based panel sheathing and a plasterboard lining. The vertical studs bear loads through the structure to the foundations. The sheathing provides resistance to wind. Thermal insulation materials are usually incorporated in the spaces between the studs of external walls. For more information see Insulating Materials.

Depending on the design of the wall, protective membrane materials may also be required. For most external walls a breather membrane on the external face of the panels protects the panels during construction. This breather membrane also provides extra defence against any wind driven rain that may penetrate the completed external cladding. A vapour control layer is usually required on the inner side of the insulation, behind the plasterboard lining, to prevent water vapour entering the wall panel. Please read more information on these materials here Insulating Materials.

The wall panels are usually designed to incorporate ducting for services. Timber frame panels can both be manufactured and supplied as Closed Panel or Open Panel Systems. The convenient service void is present in both systems. The open panel system is manufactured off-site so that once assembled on site, the first fix services can complete their works and then the wall panel can be battened and plasterboarded. The closed panel has the service void already incorporated within the panel as well as Fermacell Board which replaces the need for plasterboard. This system is popular due to the much reduced on-site labour costs as well as time saving benefits.

Environmentally Sustainable

Timber is recognised as the only renewable construction material and the softwoods used in timber frame are sourced from environmentally sustainable British and European forests. Timber frame construction gives designers a great deal of flexibility in both layout and external appearance. High levels of thermal insulation are incorporated within the construction, reducing heating costs and conserving energy. Read more on the sustainability of timber – https://www.timber-frame-suppliers.co.uk/2014/timber-frame-houses-sustainability/