New Build Home for Self-Builder in Reading

In late 2018 we were recommended to our clients in Tilehurst who were looking to build a new home for themselves in summer 2019 and with a quotation for our open panel timber frame system supplied, by April 2019 we were instructed and on the 11th June 2019 we commenced on site installing the timber frame structure.

In 9 days the ground floor has been installed along with the first floor joists, first floor panels, structural beams and steels for the roof with the trusses next to be installed.

Here are some photos of the timber frame structure being installed in sequence.

The first delivery arrived at site on a hiab lorry, which is crane assisted haulage that lifts the larger heavier items from the lorry. With limited space, the hiab was useful so we could off-load onto bearers whilst the telehandler could then lift the materials when they’re required onto the structure.

With the first floor panels beginning to be installed, the steel beams are lifted with the use of a crane which will also be used for lifting the trusses into position for the erectors to fit.

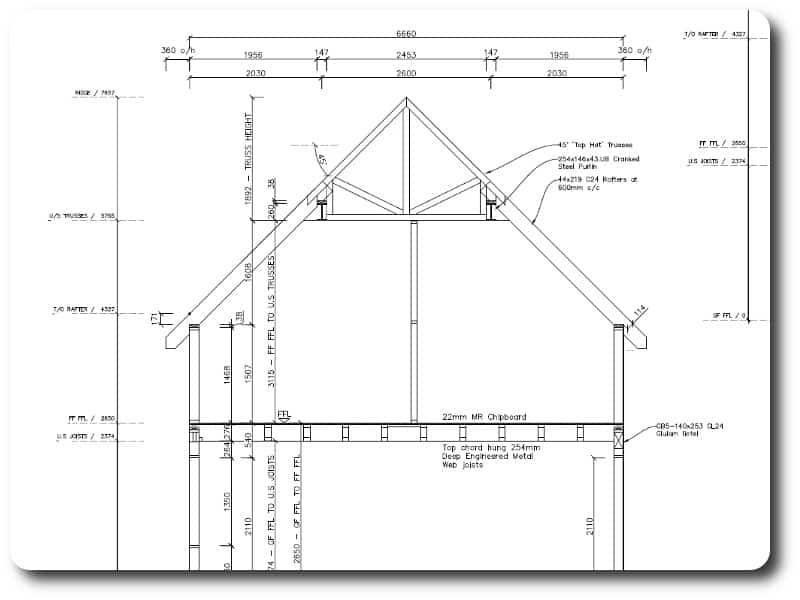

To better understand the roof, above is a snip from one of the timber frame construction drawings showing where the steels sit within the roof design.

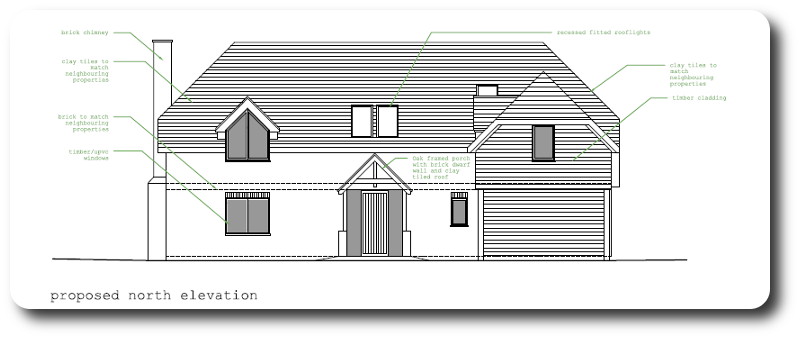

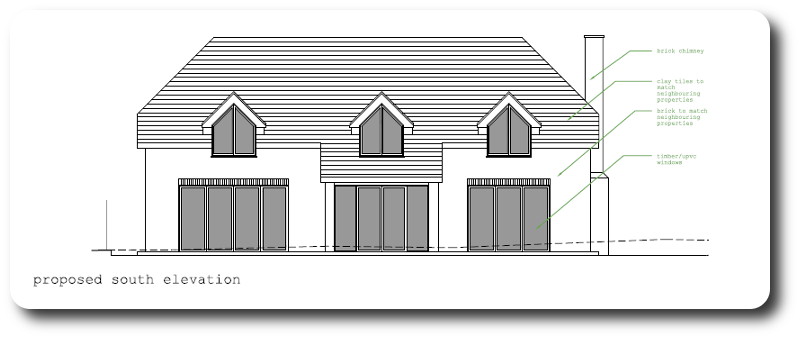

To have a better understanding of the complete structure for our Clients new build home, these are the drawings prepared by Colony Architects from which our timber frame structure was designed.

With the external cavity and brick finish the structure will achieve a U.Value of 0.16 and with the timber cladding to the front elevation, a U.Value of 0.18. To read more on the importance of U.Values and how using timber frame can achieve better energy efficiency for your new home, follow this link to our blog article explaining U Values and Energy Efficiency.

As this new build home for our Client progresses we will continue to update our website and social media with photos, so please keep checking back to see how this self-build home transforms in such a short space of time.

To contact Vision regarding your own self-build project, please contact us on 0118 971 2181 or email us at info@vision-dsl.com where we will be happy to answer any questions you may have regarding the use of timber frame for your new home